Hydraulic Rock Drill & Splitter

One excavator for your rock drilling and splitting operations

Hydraulic Rock Drill & Splitter Description

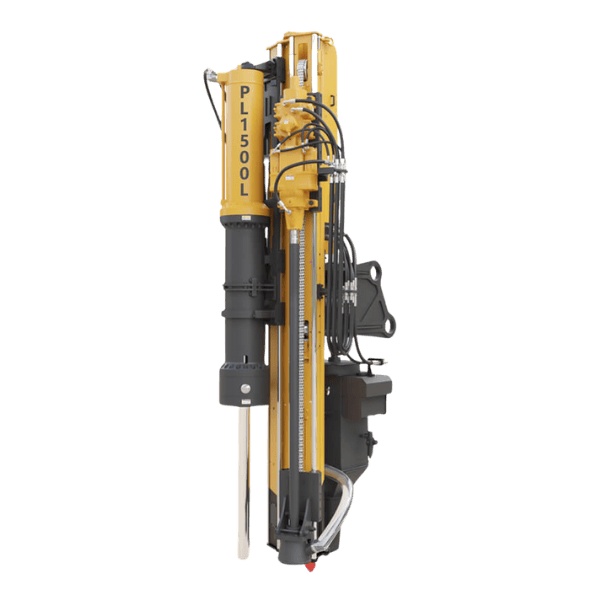

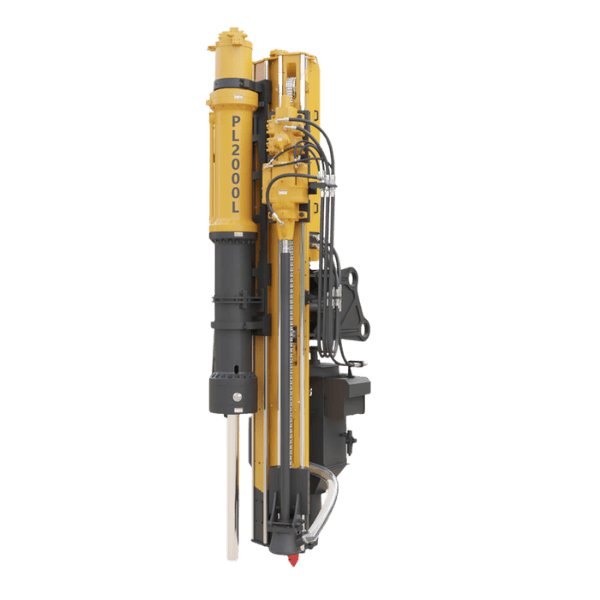

Lieyan hydraulic rock drill and splitter are used on 24-65-ton excavators. With its power and super mobility, it can be applied to various complex working conditions. In modern engineering construction, drilling and breaking rock operations are extremely common but challenging tasks. In the traditional operation mode, rock drilling and breaking require the use of different equipment, and the operation process is cumbersome and inefficient. The advent of the integrated rock drill and splitter is like a revolution in the engineering field. It successfully integrates the two functions of rock drilling and splitting, greatly improving the operation efficiency and becoming a powerful assistant for many rock-breaking projects.

The original L-shaped triangular swing articulated structure is stable and durable, can be adapted to construction at various angles, and is easy to disassemble and transport; the back-mounted circuit and hydraulic system are convenient for maintenance and repair; the wireless remote control is safer and more convenient to operate; the full hydraulic rock drill is used, the drilling is more efficient; the rock splitter uses a two-stage booster cylinder, and the splitting force is stronger.

We have three models to provide perfect solutions for different types of excavators and construction sites.

Advantages of Hydraulic Rock Drill & Splitter

Powerful functions

The rock drill, rock splitter, and excavator are perfectly connected, and one device can complete the rock drilling and splitting operations. pulvinar dapibus leo.

Efficient

Powerful power is provided by the excavator, using a fully hydraulic rock drill with a drilling efficiency of 1m/min; the rock splitter uses a two-stage hydraulic cylinder with a stronger splitting force; the comprehensive rock breaking efficiency is higher.

Economic efficiency

Reduce equipment purchase and labor costs, and only one excavator is needed to complete rock drilling and splitting operations.

Environmental friendliness

During the rock breaking operation, there is no vibration, no flying stones, no dust and noise pollution, which meets the environmental protection requirements of urban construction and protects the safety of surrounding building structures.

Safety

The whole machine is controlled by a wireless remote control and operated in the cab, which reduces the operating risks of construction personnel, improves the safety of construction, and optimizes the working environment of operators.

How does Lieyan hydraulic rock drill and splitter work ?

Lieyan hydraulic rock drill and splitter attachments are powered by the excavator and operated by the excavator handle and wireless remote control. First, operate the excavator and place the rock drill and splitter attachments on the rock location that needs to be split. Use the wireless remote control to start the hydraulic rock drill to start drilling, and control the angle, depth, and diameter of the drilling according to the construction requirements. After drilling the hole, rotate the main frame to align the splitter with the drilled hole, and then insert it into the hole. Turn on the splitting switch, and provide hydraulic power to the splitter through the hydraulic system of the excavator, so that the splitter generates strong hydraulic force to split the rock from the inside of the rock. After the splitting is completed, lift the splitter, rotate the main frame to reset, and proceed to the next round of drilling and splitting operations.

1. locate

2. Drilling

3. Lift the rock drill

4. Rotating main frame

5. Put in the splitter wedge

6. splitting

7. Lift the splitter

8. Rotate the main frame to reset

Technical specifications

| Model | PL-1000L | PL-1500L | PL-2000L | |

| Total length(mm) | 4140 | 4950 | 5400 | |

| Total width(mm) | 1500 | 1520 | 1520 | |

| Total height(mm) | 1770 | 1860 | 1970 | |

| Total weight(Kg) | 4000 | 5000 | 6000 | |

| Excavator | Total weight(ton) | 24-36 | 36-48 | 48-65 |

| power(Kw) | ≥125KW | ≥150KW | ≥180KW | |

| Total flow(L/min) | ≥240 | ≥280 | ≥360 | |

| Work Pressure(Mpa) | 30 | 30 | 30 | |

| Splitter | Cylinder diameter(mm) | 240 | 280 | 300 |

| Cylinder stroke(mm) | 800 | 900 | 1000 | |

| Work Pressure(Mpa) | 30 | 30 | 30 | |

| Work flow(L/min) | 240 | 240 | 240 | |

| Splitting force(ton) | 6500 | 8500 | 10000 | |

| Wedge length(mm) | 1000 | 1300 | 1500 | |

| Rock Drill | Impact power(Kw) | 22 | 30 | 33 |

| Impact frequency(Hz) | 38 | 40 | 40 | |

| Impact pressure(Mpa) | 18-22 | 16-20 | 16-20 | |

| Impact flow(L/min) | 120 | 200 | 220 | |

| Torque(Nm) | 800 | 1800 | 2330 | |

| Drilling diameter(mm) | 115 | 140 | 152 | |

| Air Compressor | Exhaust volume(CFM) | 176 | 211 | 282 |

| Exhaust pressure(Bar) | 7 | 7 | 7 | |

| Dust collector | Rotation speed(RPM) | 4000-5000 | 4000-5000 | 4000-5000 |

| Work Pressure(Mpa) | 18-22 | 18-22 | 18-22 | |

| Work flow(L/min) | 25-30 | 25-30 | 25-30 | |

| Filter Elements(Pcs) | 5 | 8 | 12 | |

Video

Brochure download

Hydraulic Rock Drill & Splitter Applications

Hydraulic rock drill and splitter used in road construction

Hydraulic rock drills and splitters for breaking hard rock

Hydraulic rock drills and splitters for rock excavation in foundation pits

Hydraulic rock drills and splitters for rock excavation in foundation pits

Related News